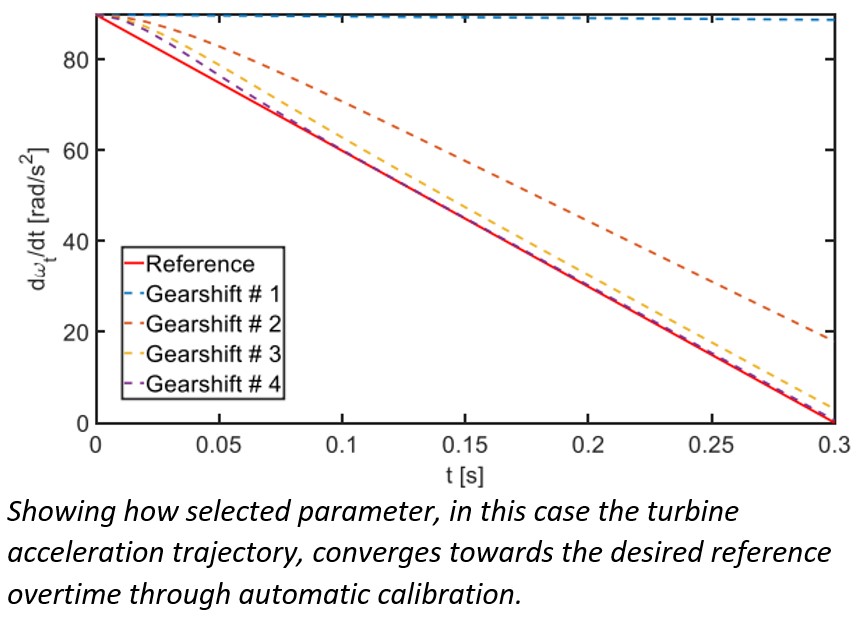

Method for Automatic Transmission Calibration and Controller OptimizationA method for automatically calibrating and optimizing gear shift control parameters through iterative algorithms both during development and during use. The NeedAs fuel efficiency standards for modern cars increase, manufacturers are adding more and more gears to their transmissions. The higher number of gears allows for greater gear spread, meaning engineers can add taller gears that allow engines to operate at lower, more fuel-efficient rpms. Despite knowing more gearing is better for engine efficiency, manufacturers have tended to avoid adding more gears because the increase in efficiency gained at the engine was not enough to offset the energy losses at the transmission, losses mainly from increase in the number of shifts required when more gears are available. Still under pressure to increase fuel efficiency, some manufactures have considered continuous variable transmissions or CVTs that have a theoretically limitless number of available gear ratios to ensure the engine is always operating at its most efficient speed. However, CVTs are often expensive and lack the torque of traditional transmission. A better approach is to find ways to reduce losses from shifting in traditional automatic transmission so that the gains from increased gearing may be retained. The TechnologyProfessor Krishnaswamy Strinivasan and PhD candidate Kirti Mishra have developed a method for automatically calibrating gearshift controllers for automatic transmissions. In the first instance, the method applies to the initial stage of transmission calibration, where a calibration engineer typical spends a large amount of working hours adjusting and tuning gearshift control parameters as part of the overall development of a new transmission. After development, the method also works during the regular operation of the vehicle, adapting control parameters over time as transmission characteristics change due to wear and tear. The method uses iterative learning to adapt control inputs for the next gearshift based on readings from the previous shift, and a linear varying control technique for feedback control during discrete phases of the shift. Once provided with an appropriate feasible region on the speed-torque plane for all legal gearshifts, the algorithm converts the region into a calibration grid. At every point on the grid an initial condition involving a rough estimate of the desired control parameter is then modified overtime through discrete iterations until the transmission is calibrated. A separate algorithm is used for adaption of gearshift control parameters in the transmission controller during regular operation of the vehicle. In general, the algorithm adjusts control parameters in real-time so that the parameter, be it fill time or torque value always fall within the desired range. This accounts for production differences from one transmission to another and for expected changes over time due to wear and tear. For instance, during the fill phase online algorithm chooses when to initiate the fill operation for the oncoming clutch by varying what percent decrease in turbine acceleration is sufficient to initiate a gearshift until the fill time falls within the desired tolerances. Commercialization

Benefits

Patents

|

Tech IDT2019-124 CollegeLicensing ManagerZinn, Ryan InventorsCategoriesExternal Links |